NX Metrology is coming soon. We are integrating the entire workflow for complete automation of the part manufacturing, including On Machine Probing and CMM.

Trends & Facts, experience, forecast and motivation

It is very hard to guess what is coming after COVID-19 in the PLM domain other than the previous years forecast regarding cloud deployment, augmented reality and artificial intelligence.

It’s specifically difficult to predict future in the part manufacturing area, due to its traditional, conservative way of conduction. We can be sure that the market will experience some rollercoaster type of ups and downs and might not achieve a stable status in the upcoming years.

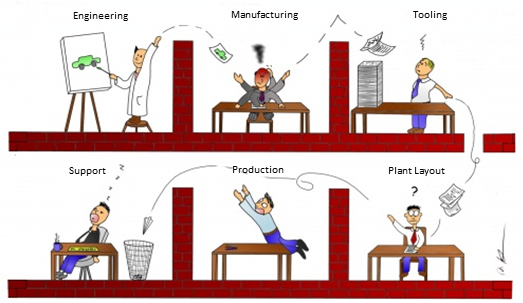

With the remote working experience, we see that communication between different engineering and production teams is becoming more and more critical: using and collaborating on consistent, always up-to-date data in all the part manufacturing processes become more important than ever. „Over the wall” type of approach puts companies in difficult situation, so process integration is key and most critical aspect of efficiency and cost.