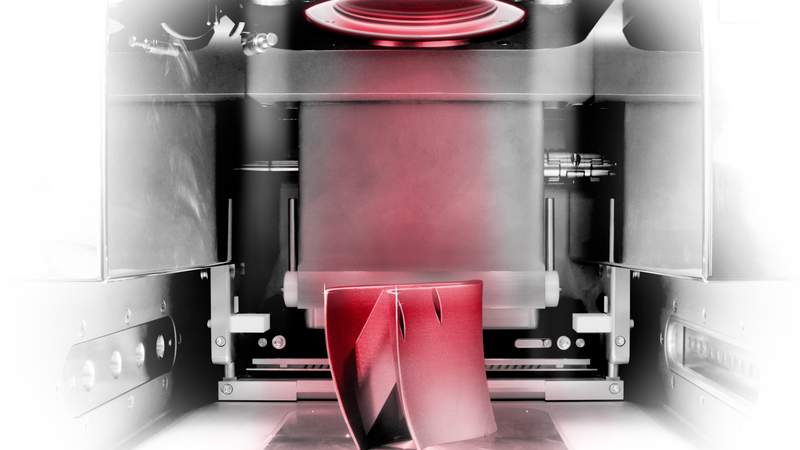

CAM

Computer Aided Manufacturing

Computer Aided Manufacturing includes the part of the manufacturing process in which the design of a component is created as manufacturing information and is provided for the actual manufacturing process.

The current challenges in this area are speed, flexibility and cost reduction, in order to be able to respond appropriately to the increasing time and cost pressure and the variety of models.

In our experience you can overcome these challenges with an integrated software system. A system that is good to use, has excellent functionality, but above all has appropriate optimisation and automation capabilities. Put simply, a CAM system.

Advantages of a CAM software

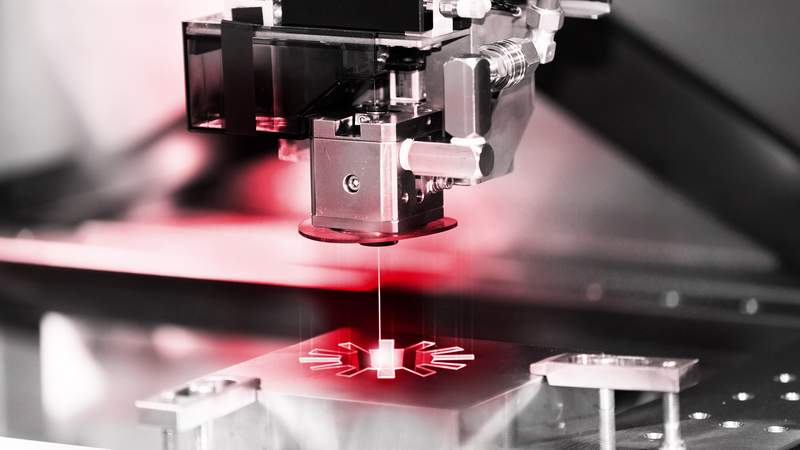

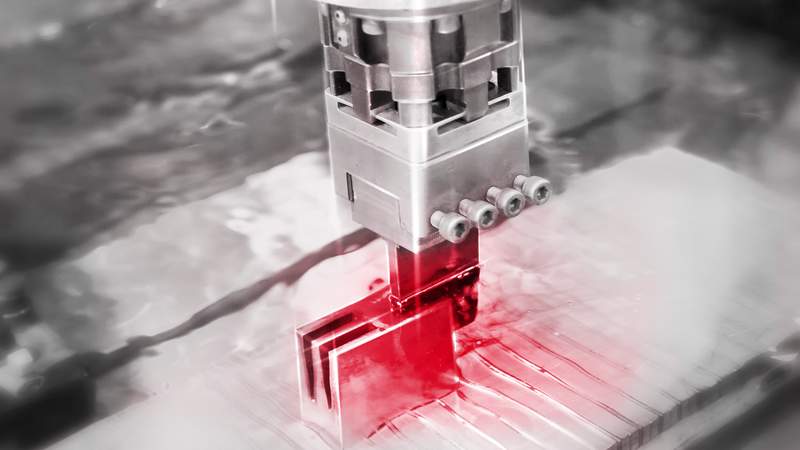

- Exploitation of the capabilities of the manufacturing equipment such as high-speed, five-axis, multi-functional and milling machines, EDM machines and measuring machines

- Fast, efficient derivation of manufacturing information (e.g. NC programmes)

- Complete data management – up-to-date manufacturing information in any form, at any time, anywhere

- Fast, error-free response to changes in the process (customer requirements, manufacturing requirements, production modifications, etc.)

- Optimum linking and connection with the workshop, additional systems (tool management, ERP technology) and suppliers

You can overcome these challenges with NX CAM from the Siemens Digital Industries Software product portfolio. We bring you...

- NX CAM - The CAM system from Siemens Digital Industries Software

- Data management in the manufacturing process

- Workshop connection

- Automation capabilities

- Customised tool management

- OMP - measurement on the NC machine

- New manufacturing process

- Efficient manufacturing process

Our references

*Mandatory fields